.png) What is Investment Casting?

What is Investment Casting?

Investment Casting is a metal forming technique that uses a non-metal mold formed around a pattern of wax or similar material which is then removed by melt-ing. Molten metal is then poured into the mold and left cool. After unmolding the desired metal part is formed. The most commonly applied process is Lost Wax Casting.

.png) Why Investment Casting?

Why Investment Casting?

Investment casting is valued for its ability to produce components with accuracy and fine surface finish that requires little machining. They can also be cast with thin walls and complex shapes, with high mechanical properties. In addition, it gives flexibility for product design and small batch and variety production to adapt changing market demand.

.png) Applications

Applications

Subject to the technical conditions of foundries and the specification required for castings, this process can be applied in different fields, including hardware parts, industrial components, valves, pneumatic tools, golf club heads, automotive parts, medical devices and implants, and aerospace parts etc.

.png) Process

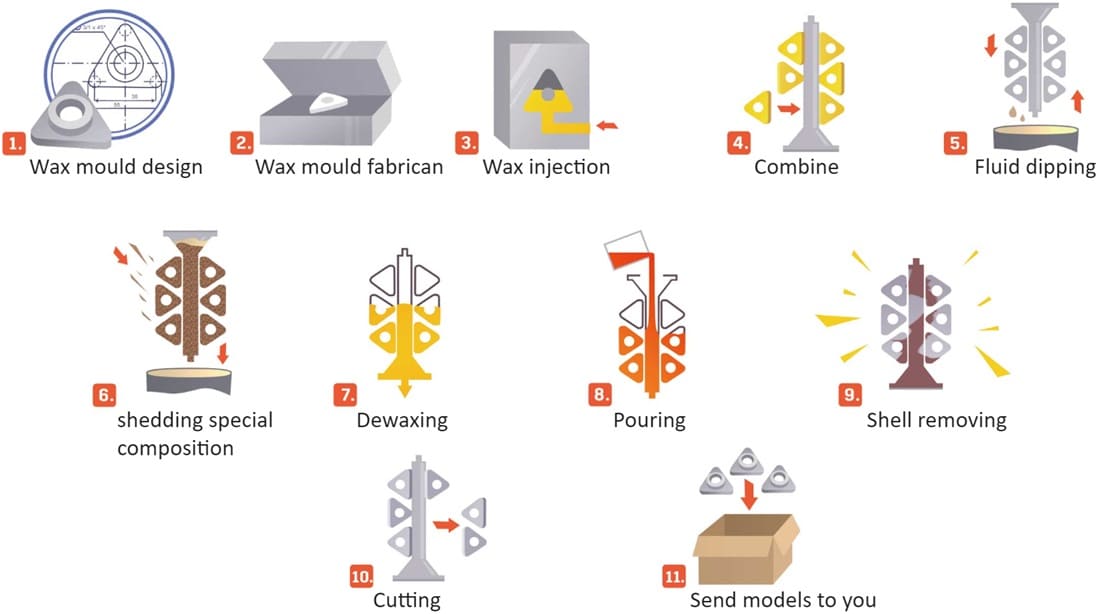

Process

.png) Materials we provide

Materials we provide

Wax Injection System

- Pattern Wax

- Stick Wax

- Water Soluble Wax:General, Eco-friendly

- Patch Wax

- Sprue Wax/Extrusion Wax

- Mold Release Spray:

- Traditional (Silicone Oil Based),

- Eco-friendly (Water Based)

- Zircon Sand/Flour

- Mulcoagrain Sand/Flour

- Mulright Sand/Flour

- Refractory Flour

- Fused Silica Sand/Flour

- Calcia Stabilized Zirconia Sand/Flour

- Plaster for Investment Casting

- Colloidal Silica Binder

- Composite Colloidal Silica Binder

- Ammonium Zirconium Carbonate (AZC)

- Ethyl Silicate

- Wetting Agent

- Anti-foaming Agent

- Ceramic Shell Modifying Agent

- Shell Dryness Indicator